With 3.4 million ha of forests, Latvia is among the most forested countries in Europe – and half of Latvia’s forests are managed by JSC Latvijasvalstsmeži (LVM). Established in 1999, the company has the mandate to sustain and increase forest value, maximizing value through good forest management. The total area managed by LVM accounts for 1.63 million ha, of which 1.60 million ha are forestlands. Timber is the company’s major product.

Modeling large, complex forest operations

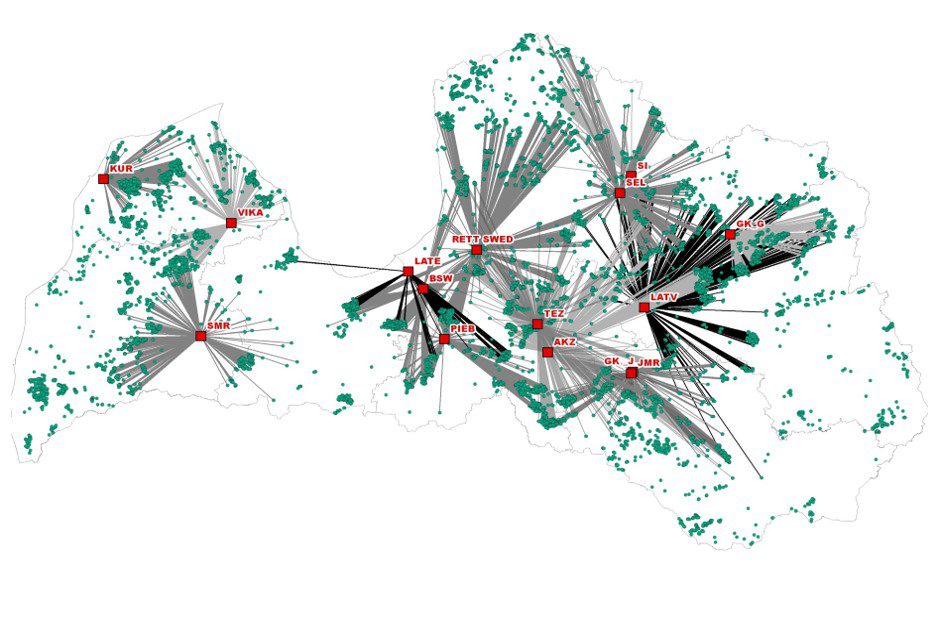

LVM harvests approximately 12,000 harvest units per year with an average size of 1.9 ha resulting in 4.9M m3 of wood against a mixed wood basket that produces almost 80 species/product sorts. Feeding more than 50 domestic Roundwood mills and export pulpwood markets, operations for harvesting, transportation, and roading are large and complex. Products are shipped long distances to meet domestic and export markets where an individual harvest unit produces up to 16 products.

Decision support for harvest and delivery scheduling

LVM implemented an Operational Planning solution (named OPT), utilizing Remsoft’s Woodstock optimization modeling platform, to help manage this complex supply chain. Since 2011, they have been using their OPT solution as decision-support for monthly and annual forest plans, to optimize wood assortment production and delivery planning.

Using OPT, harvest and delivery schedules are created and updated several times a month and shared throughout the organization. Planning reflects the needs of the sales, production, and supply organizations and considers forestry restrictions and conditions.

Reduced costs and improved fulfillment

With multi-level planning and optimization, LVM was able to reduce their transportation costs, improve contract fulfillment execution and reduce product downgrade – as well as optimizing monthly and yearly production planning, strategic planning, and tactical planning.

Two key factors have resulted in substantial transportation savings. First, there has been a significant reduction of total distances driven with and without load. Secondly, transportation distance is not rising year over year despite ongoing weather condition complexity and overall plan changes for each year. This is significant because their trucks drive over 25 million kms to 140 destinations every year. Based on their calculations, LVM has cut a minimum 2 km from each round trip since implementing OPT and has seen an estimated 4% reduction in transportation cost, saving €1,200,000 annually.

From 2011 to 2015, LVM experienced a 9% improvement in contract fulfillment, resulting in happier customers, as well as an overall improvement in their ability to meet product and species mix requirements.

Better planning has helped to reduce the loss of potential revenue from product downgrade by 5% from 2013 to 2014, and 17% from 2014 to 2015. They also reduced product storage needs and improved their inventory management.

The end result is measurable, bottom line savings and a worthwhile return on investment for LVM.

We can effectively steer and manage our complex supply chain, on both an annual and monthly basis. We can model scenarios, allowing us to make better decisions about our operations and sales processes, and provide our clients a high level of service in our delivery process. This has resulted in significant cost savings to LVM.”

Andris Balodis, Director Timber Production and Deliveries