The road network used to transport timber is the backbone of the forest supply chain. It’s also one of the costliest investments for forest companies. Timing is key. If road construction or maintenance schedules don’t synch with harvesting schedules, costs can spiral and opportunities may be lost.

But what if, in the early planning stages, you could incorporate roads into your model to determine, for instance, the best route from forest to mill or whether building a bridge to connect harvest areas is worth the investment

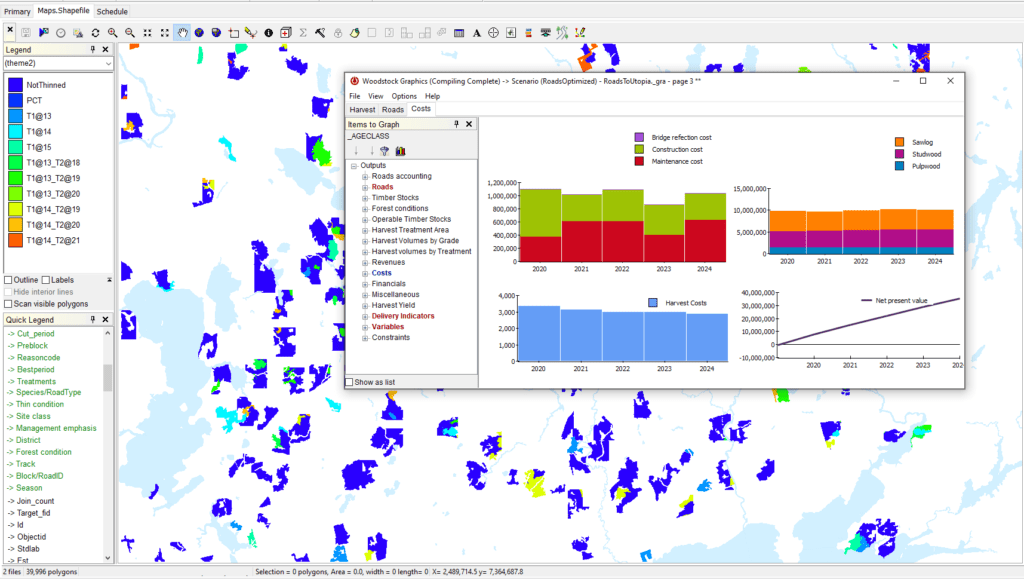

Remsoft’s Tactical Optimization application includes road planning optimization capabilities that were designed to target this challenge. It can inform road planning decisions by creating a unified harvest and road model that facilitates harvest scheduling and wood allocation. The module evaluates millions of choices to determine whether the reduction in transport costs justifies the expense of road building or maintenance. It even supports transport by rail and water.

Here are some of ways you can use Tactical Optimization to link two pillars of the forest supply chain, the road network and the harvest, while managing various constraints.

Cycle Time

Cycle time is the time it takes to complete a return trip from origin to destination, taking into account distance, average speeds, checkpoints and rest stops.

The better the condition of the road, the faster your trucks can travel. And the faster your trucks can travel, the fewer you will need. By transporting the same payload over a shorter cycle time, you save on transportation costs.

Optimizing your road planning can help you determine if the gains in cycle time and the consequent cost savings are worth the capital cost of upgrading a road.

Lead Time

Lead time is the length of time required before harvest to complete road work to avoid harvest delays and supply chain disruptions.

The shorter the lead time, the higher the road preparation costs because of the lost opportunity to implement less expensive methods. Contractors may charge a premium for a rush job, for example, or materials such as gravel may become more difficult and costly to source.

With road planning optimization you can determine the optimal lead time between road preparation and harvest to minimize costs. It considers not just the harvest schedule, but the entire supply chain and its related commitments and capabilities.

Alignment

If your road plan is created separately from the harvest plan, you will more than likely have to change both plans repeatedly.

Your road engineers may have to incorporate more road work than they had expected or have the resources to achieve. This scenario is especially true in organizations that have multiple harvest managers with separate plans, but only one road department.

Tactical Optimization plans your harvest and road network together so that the entire operation is aligned. Alignment reduces the need to revisit the plan repeatedly as a result of road readiness, road access and permitting issues.

Road Impacts

Road activity has impacts on the environment such as river sedimentation, noise, and habitat disturbance. Roads on public land may need to be decommissioned to limit post-harvest activities and liability.

Tactical Optimization helps reduce the geographic spread of harvesting activities, and therefore road activity, by adding road and access logic to the strategic model to encourage clustering. It can also be used to plan road decommissioning.

Clustering

Clustering is the act of scheduling harvests of proximate units within a given time span.

Clustering reduces the time it takes supervisors to check on their crews, the costs of maintaining roads, allocating equipment, and hauling wood, and the amount of non-productive time. Clustering can even reduce the cost of future forest operations such as tree planting and site preparation.

However, spatial constraints such as green-up delays or adjacency restrictions can limit the opportunities for clustering in the short term.

Green-up delay functionality is built into our Tactical Optimization application to allow for adjacency constraints in the optimization model. The model then adjusts the harvest timing to capture road cost savings while at the same time respecting constraints.

Seasonal Capacity

Depending on the location of your land base, there may be limitations on when you can use your established road network. Some of these limitations are predictable. In northern climes, for instance, you may not be able to use road capacity to its fullest during the spring thaw, when there are weight restrictions.

In order to maintain the payload during this period, alternative routes may be considered. These alternative routes are often more expensive because of longer distances and/or poorer road conditions.

With Tactical Optimizaion, you can schedule transport on the most attractive route until it is no longer feasible, rerouting traffic to the more expensive relief road only when necessary. It can also be used to understand the impact of less predictable events such as a mudslide or flood.

In conclusion, by optimizing your forest and road assets within the same tactical model, you can easily weigh the benefits of reducing transportation costs – and increasing the net value of your wood – against the capital cost of investing in road infrastructure.

LEARN MORE:

-

Find more information on the capabilities of Remsoft’s Tactical Optimization application and how it can help to improve wood flow, delivery, and capacity planning.

-

Get a free assessment on readiness requirements and the advantage of incorporating transport network and roading activities into your Woodstock model.