Artificial intelligence (AI) and machine learning (ML) technologies are revolutionizing supply chains across the globe, enabling companies to increase efficiency and margins by learning from data collected hour after hour, day after day. For forestry, this provides a transformational opportunity to complement existing forestry planning practices based on prescriptive optimization modeling. It also has the potential to become a new and vital best practice in operational forest operations management. By leveraging AI/ML predictive algorithms, companies can generate and improve the data they use to create optimization models, leading to a continuous improvement cycle that results in better business outcomes.

Forest supply chain dynamics

The forestry supply chain is complex. Trees are biological assets and are subject to environmental factors, sustainability concerns, and changing market conditions. Unlike brick-and-mortar warehouses, forests are spread out over vast and varied geographical areas containing thousands of individual harvest units that can range in size from one acre to 100 acres or more. It is not unreasonable to think of each harvest unit as its own warehouse full of inventory that not only changes season after season but is also usually estimated sporadically. While the volume of timber in one harvest unit may have been fully assessed by a ground crew one season before harvest, the volume estimate on another may be the result of aerial photo interpretation performed several years ago. In addition, these warehouses are often difficult to access, requiring significant investment in roads and infrastructure.

Given this complexity, planners have to balance market demand and business objectives with operational constraints and ever-changing conditions in the forests. Decisions made in response to daily challenges can have a downstream impact that can further reduce already small margins. For instance, if a road is inaccessible to one planned unit, which unit should you send the harvesters to instead to ensure you meet your mill needs? And, how can you be sure the volume estimated for the harvest unit is accurate? A wrong decision can lead to lost value and unfulfilled orders.

Improving outcomes with optimization

As a prescriptive technology, mathematical optimization helps address the complexity of operational planning by creating a formal description of the system using the language of mathematics. It encapsulates the many parameters at play in the supply chain, such as unit inventories, productivities, treatment, and timing options, along with various goals and constraints. Optimization models are formulated with mathematical programming methods, such as linear programming (LP) and mixed-integer programming (MIP), and then solved using an enterprise-class solver that generates a solution representing the best path forward. In operational forestry, this solution is an optimal and feasible harvest and delivery schedule that balances revenue and volume objectives with business and sustainability constraints.

Mathematical optimization is an industry-standard approach to enterprise forestry used by companies around the world to tackle planning problems ranging from strategic to operational. This is because it does what the human brain can’t do; it evaluates the millions upon millions of choices in the solution space to arrive at a single solution that represents the best possible outcome given the data provided.

This, of course, means that optimization models are highly dependent on the underlying data assumptions, and the quality of the solution will be driven by the accuracy of the data available. Optimization may tell you the best unit you should send your crews to when the road goes out, but if the volume estimate on the unit was wrong, you may still be left with unhappy customers. This is where AI/ML can help.

Boosting data intelligence with AI

Boosting data intelligence with AI

As in many industries, forest companies are collecting more information about their operations. This can result in several years of intelligence related to the performance of their forestland. With every unit harvested, companies collect and store the specific product volumes generated by the unit, adding it to the known attribute information that has already been acquired, such as slope, soil type, and other relevant unit characteristics relevant. Performance measures are also collected related to the crew, machines, and treatments employed during harvest. This means companies not only know exactly what volume came from a unit but also how long it took to harvest it.

For AI/ML models, this information is a gold mine. AI/ML is a predictive data science that utilizes machine learning algorithms, such as decision tree, logistic regression, and linear regression to train models capable of predicting future results based on past performance. Using the forest planning example, this means companies can leverage data from past harvest units to predict the volume on future units with similar attributes.

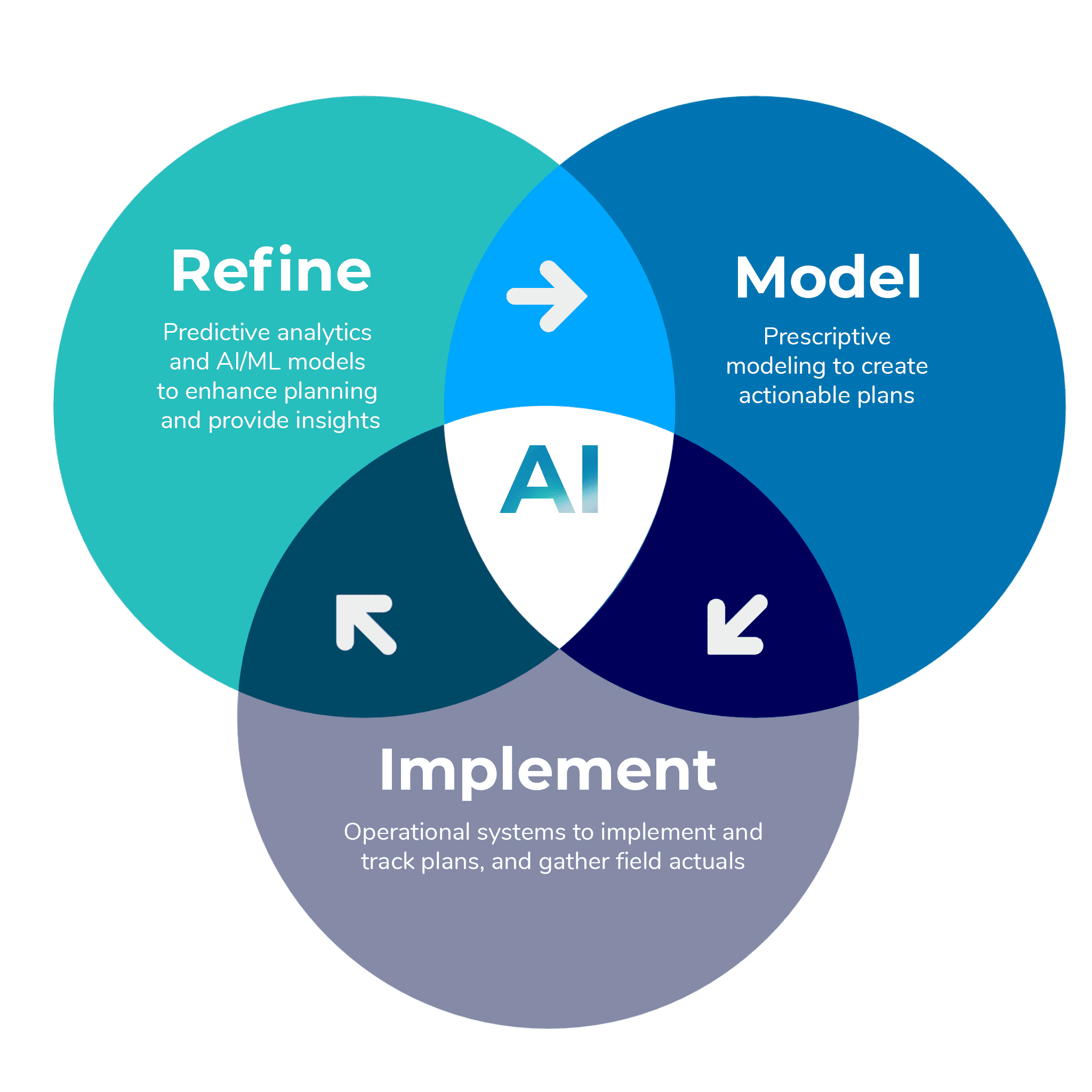

When combined with mathematical optimization, this creates an opportunity for a continuous improvement cycle based on complementing mathematical optimization models with AI/ML models. In this cycle, AI/ML can be used not only to refine and validate data assumptions based on past performance but also to generate new predictions where there are gaps in data. Optimization models can use this refined data to create optimized and actionable plans that, when implemented, generate further data to continue training the AI/ML models. Through each cycle, data accuracy improves, leading to better schedules, and ultimately, to better business outcomes.

Furthermore, while the continuous improvement cycle assumes AI/ML models will be run before mathematical optimization, they can also be used after the schedules are generated to allow planners to uncover and analyze variances between the assumptions used in optimization and the predictions made by AI/ML.

Driving continuous improvement

With the increasing and widespread adoption of AI/ML technologies in supply chains worldwide, it is clear that AI/ML offers a compelling complement to mathematical optimization modeling and can enhance the existing best practices already used in enterprise forestry. In an industry where margins have always been slim, the opportunity to drive continuous improvement and boost business outcomes with AI/ML and optimization is transformative and should not be ignored.

[Originally published in Supply & Demand Chain Executive magazine.]

LEARN MORE:

- Read how companies are connecting data and analytics in the cloud with Remsoft Operations to provide real-time decision support for forest operations planning.

-

Get an overview of Remsoft Operations capabilities for operational planning and scheduling, and download the datasheet.